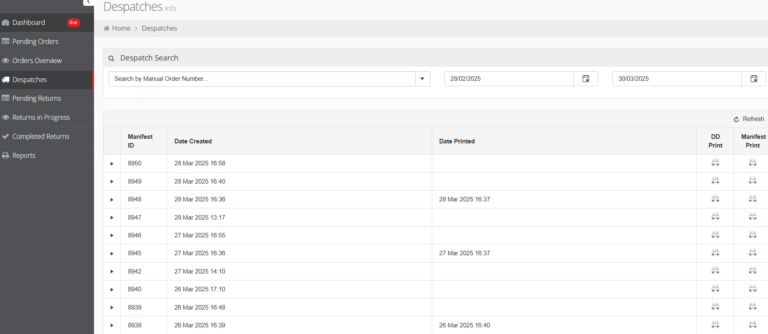

AI-Powered Logistics & Supply Chain in New Zealand: Route Optimisation, Real-Time Tracking & Last-Mile Wins

AI is transforming logistics and supply chain management in New Zealand. From route optimisation and real-time tracking to smarter last-mile delivery, transport and freight companies can reduce costs, overcome fuel and labor challenges, and boost efficiency with modern logistics software NZ and AI delivery solutions.

New Zealand’s transport and freight sector runs on tight margins, long distances, variable weather, and a constant juggling act between urban congestion and rural coverage. Add rising fuel costs, driver and warehouse labour shortages, and stricter customer SLAs—and you get the perfect case for AI. In this post, we’ll unpack how logistics software NZ players are using AI to cut kilometres, improve ETAs, and make AI delivery NZ a practical, bottom-line advantage—especially in freight management New Zealand wide.

Why AI, and why now?

Pressure points for NZ operators:

- Fuel volatility: even small per-litre swings make or break profitability on multi-stop routes.

- Labour shortage: fewer qualified drivers and pick-pack staff means you must schedule smarter.

- Customer expectations: live ETAs, proof-of-delivery photos, and tight delivery windows are the norm.

- Geography & infrastructure: long intercity runs, rural last-mile, and occasional ferry constraints (North–South).

- Compliance overhead: RUC for diesel, maintenance schedules, safety audits—admin you can’t ignore.

AI doesn’t “replace” dispatchers or drivers; it augments them with better predictions and faster, data-driven decisions.

Core AI capabilities that move the needle

1) Route optimisation that reflects NZ reality

Classic “shortest path” isn’t enough. AI models consider:

- Traffic patterns (peak Auckland corridors vs. off-peak provincial runs)

- Delivery time windows & priority loads

- Vehicle constraints (weight/volume, refrigerated, tail-lift, EV range)

- Ferry schedules / remote roads when relevant

- Backhaul opportunities to avoid empty legs

Result: fewer kilometres, fewer trucks to do the same work, and fewer late deliveries.

2) Real-time tracking & dynamic ETAs

Combine GPS telemetry with live conditions and historical performance to produce ETAs that update themselves. Share them with customers via SMS/email or a branded tracking portal. AI flags which stops are at risk and suggests resequencing on the fly.

3) AI-assisted last-mile dispatch

For dense city runs or rural drops, AI clusters stops into micro-zones, assigns the best driver automatically, validates addresses, and adjusts routes mid-shift when a customer isn’t available or a road closes.

4) Demand forecasting & roster planning

Use historical orders, seasonality, day-of-week trends, and promotions to forecast orders by region and service level. That feeds rosters (drivers, pickers, cross-dock) and fleet allocation so you aren’t over- or under-staffed.

5) Load building & dock/yard optimisation

AI packs pallets and cages by volume, fragility, and unload sequence, minimising re-handles at receivers. Slotting and dock schedules adjust automatically when line-haul ETAs slip, protecting turnaround times.

6) Predictive maintenance

Anomalies in fuel burn, engine temps, brake wear, or vibration data trigger early interventions. Fewer breakdowns, less unplanned downtime, safer fleets.

7) Exception management that saves your day

When a driver logs a “can’t deliver” reason, AI recommends the next best step: re-attempt later, redirect to pick-up point, or consolidate with tomorrow’s run—complete with customer comms templates and ETA updates.

Last-mile delivery in NZ: what’s different—and how AI helps

Challenges:

- Low delivery density outside major centres increases cost per stop.

- Address quirks (new subdivisions, rural delivery points).

- Weather variability affecting slipways, gravel roads, and timing.

AI tactics:

- Dynamic zone planning: adjust territories daily based on order mix.

- Address intelligence: auto-corrects, geocodes, and learns successful drop points.

- Auto-consolidation windows: nudge customers to pick delivery slots that reduce deadhead.

- Driver guidance: “last 100 metres” notes, property photos, gate codes—learned from prior successful attempts.

What to look for in logistics software (NZ buyer’s checklist)

Whether you’re upgrading your TMS or piloting AI delivery NZ features, prioritise:

- Local fit: NZ address formats, RUC awareness, GST-friendly invoicing, and regional carriers.

- Open integrations: ERP/WMS (Xero, MYOB, Microsoft, SAP), e-commerce, scanning, and telematics.

- Real-time ETA sharing: customer-facing links, branded notifications, POD with photos/signatures.

- True optimisation engine: multi-vehicle, time windows, load/weight constraints, and live resequencing.

- Driver app UX: offline mode, clear stop flow, barcode/QR, photo capture, safe driving prompts.

- Analytics: cost per drop, on-time %, first-attempt success, km per stop, utilisation, CO₂ per shipment.

- Security & compliance: role-based access, audit trails, NZ data residency or clear data governance.

- Time-to-value: pre-built NZ carrier/service templates, configurable without heavy custom code.

Implementation roadmap (practical and low risk)

- Data health check: clean addresses, unify SKU/dimension data, confirm fleet capacities.

- Pilot one lane/region: choose a representative metro + regional mix; instrument everything.

- Integrate telemetry & orders: connect order feed, driver app, and GPS.

- Turn on AI routing in shadow mode: compare optimised vs. dispatcher routes for a week.

- Go-live with customer ETAs: start with B2B receivers that benefit most from predictability.

- Scale & refine: add predictive maintenance, load building, and exception playbooks.

KPIs that prove AI is working

- Km per stop ↓ 10–25% (varies by density and constraints)

- On-time delivery ↑ 3–10 pp

- First-attempt success rate ↑ 5–15 pp (fewer redeliveries)

- Fleet utilisation ↑ (more drops per vehicle/day)

- Customer contacts per order ↓ (self-serve ETAs)

- CO₂ per shipment ↓ via fewer km and better consolidation

Frequently asked questions (NZ-focused)

Is AI overkill for small fleets?

Not at all. Even 10–20 vehicles benefit from better clustering, ETAs, and driver guidance. Savings compound quickly.

Do we need perfect data first?

No. Start with your best order + address data. Modern platforms improve data quality as you operate.

How fast can we see results?

Teams typically see route and ETA improvements in week one of a controlled pilot, with fuller savings as forecasting and load planning kick in.

Will drivers accept it?

Yes—if the driver app is simple, reduces admin, and helps them finish on time. Involve drivers early and fold in their feedback.

For deeper insights into how AI is reshaping last-mile logistics in the ANZ region, check out this article: [AI in Logistics: Transforming Route Optimisation and Last-Mile Delivery for ANZ Businesses].

And if you’re evaluating logistics software in NZ, this roundup of the 20 Best Logistics Software in New Zealand (August 2025) offers a helpful recap of top tools available locally.

The takeaway

AI has moved from buzzword to profit engine for freight management New Zealand wide. The combination of route optimisation, real-time tracking, and smart last-mile dispatch lets NZ transport companies absorb fuel volatility, do more with constrained labour, and keep customers informed without endless phone calls.

If you’re exploring logistics software NZ or want to pilot AI delivery NZ capabilities—route optimisation, dynamic ETAs, POD workflows—let’s map a low-risk trial on one of your lanes and prove the ROI in days, not months.

Want a tailored demo or a pilot plan for your operation? Get in touch and we’ll put an NZ-specific blueprint together for you.